Description:

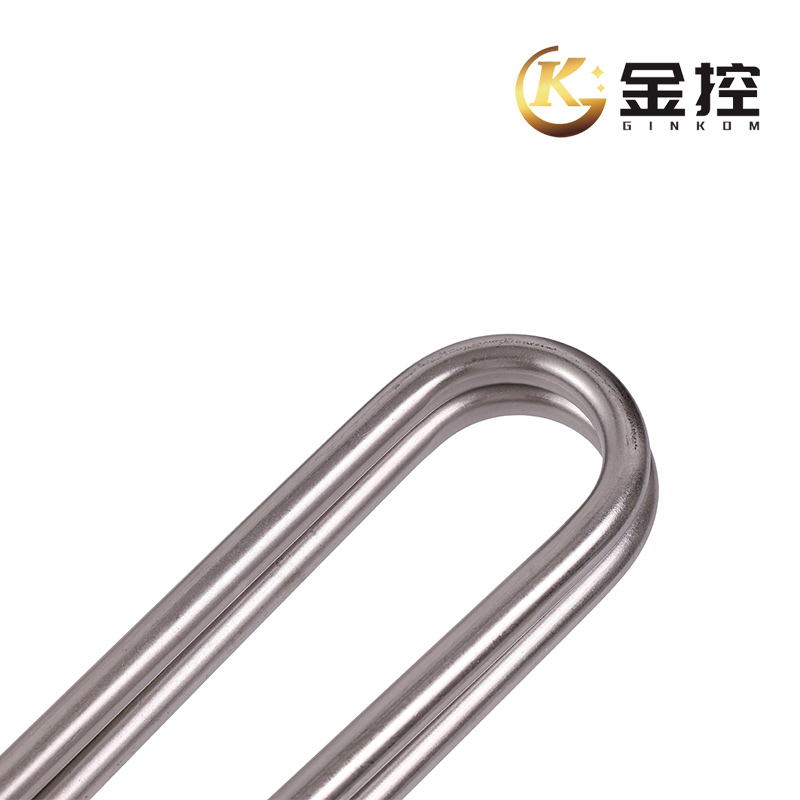

Formed tubular heater is another of tubular heater. Tubular Heating Elements are the most versatile, dependable and rugged of any heat generating device. It is widely used the source of electric heat for industrial, commercial and scientific field. And it is an ideal heat source for this field. Tubular heater is the core of most common heating solutions found today. It can be designer all kinds of materials, shape, electrical ratings, terminations and sheath materials.

Tubular Heater are a mineral insulated, metal-sheathed electric resistance heater. We use the safest and cost-effective materials to produce safe and stable products for our customers.

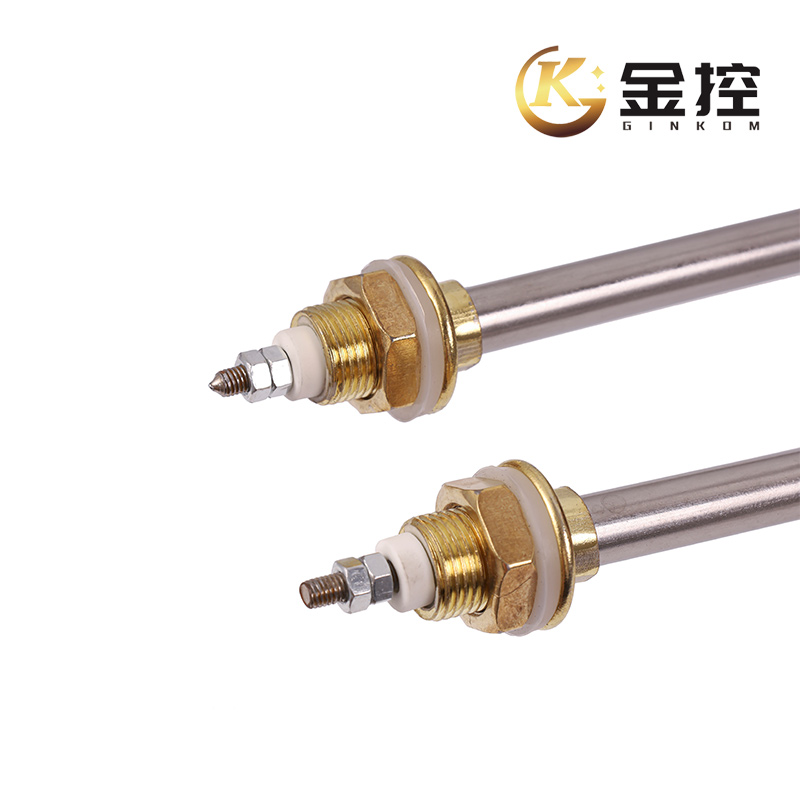

Tubular heater has 4 basic components:

- Metal sheath

- MgO

- Helix resistance coil

- Cold section at each end

A variety of materials are available for different application conditions. These take into account corrosion and temperature factors. Let us help you choose the optimum material to ensure the longest possible life and the safe for your application.

Specification:

| Sheath Material | Sheath Max. Temp | Application | Sheath Dia | Sheath Length |

| Copper | 150℃ | Water, Non-corrosive liquids | 6~25mm | 200~8000mm |

| Steel | 400℃ | Oil immersion | 6~25mm | 200~8000mm |

| Stainless steel 304 | 650℃ | Water, Corrosive liquids, Food processing | 6~25mm | 200~8000mm |

| Stainless steel 316 | 650℃ | Corrosive liquids | 6~25mm | 200~8000mm |

| Stainless steel 321 | 650℃ | Intergranular corrosion situation | 6~25mm | 200~8000mm |

| Incoloy 800 | 800℃ | Water, Corrosive liquids, Air, Clamp-on | 6~25mm | 200~8000mm |