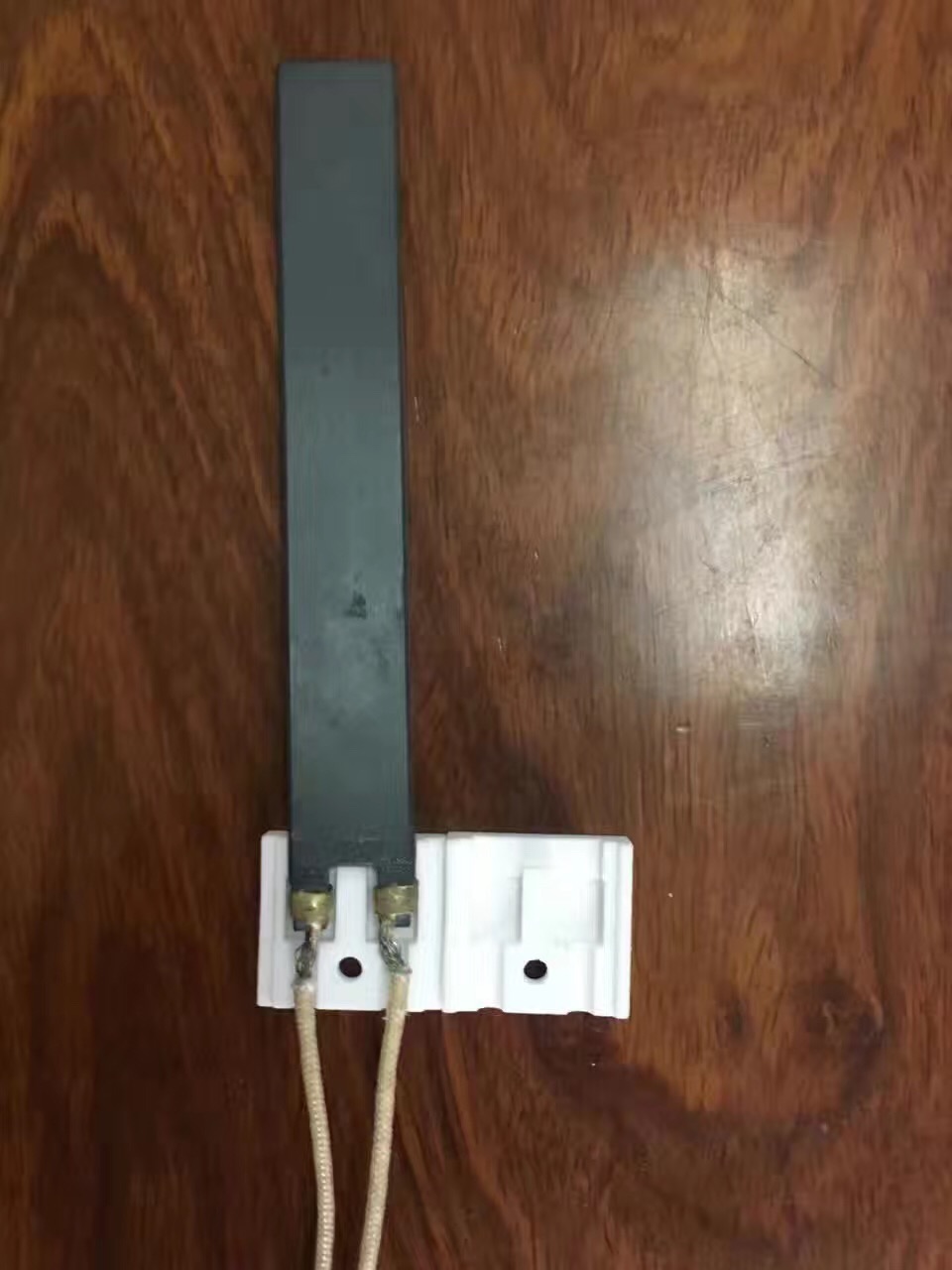

Description:

Silicon nitride heating elements are widely used in the field of instant heating appliances due to their high thermal efficiency, good electrical safety performance and fast temperature rise. The silicon nitride electric heating element is composed of a heating tungsten wire, a molybdenum wire and a silicon nitride matrix. The heating tungsten wire is placed in the silicon nitride matrix as a heating source. The molybdenum wire is connected to the heating tungsten wire as a lead electrode and leads out of the silicon nitride matrix. Since the heating tungsten wire has a significant impact on the heating effect of the silicon nitride electric heating element, the shape and arrangement of the heating tungsten wire, as well as the selection of the specifications of the heating tungsten wire itself, are technical difficulties in this field.

Specification:

| Applicable Industries | Biomass boiler igniter, straw incinerator igniter, Biomass steam generator igniter, Biomass burner igniter, Hot air gun, lighter gun, welding torch, Fireplace Ignition, Pyrotechnics generator ignite, Barbecue point charcoal, Oil and gas igniter |

| Main Material | Silicon nitride |

| Working Temperature Range | 0 – 1200 ℃ |

| High surface loading | up to 25w/cm2 |

| Length of ignition | 70-140mm |

| Advantage | Acid-resistant and alkali corrosion |

| Frequency | 50 / 60Hz |

| Electrical strength of insulation | 2500V, 50Hz at room temperature, 1 minute without breakdown phenomenon |